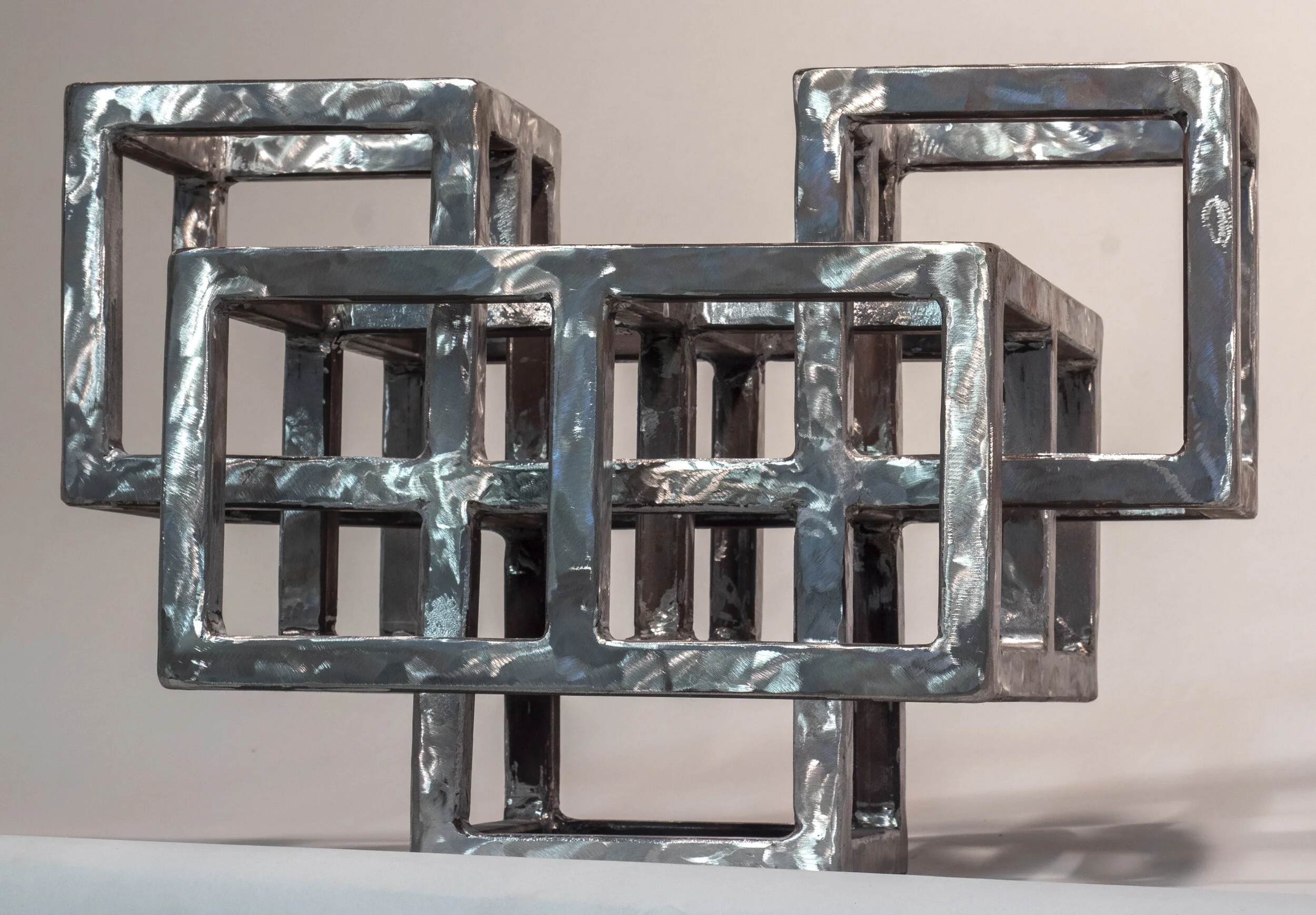

The Creative Kid

Work by Dallas Hartman

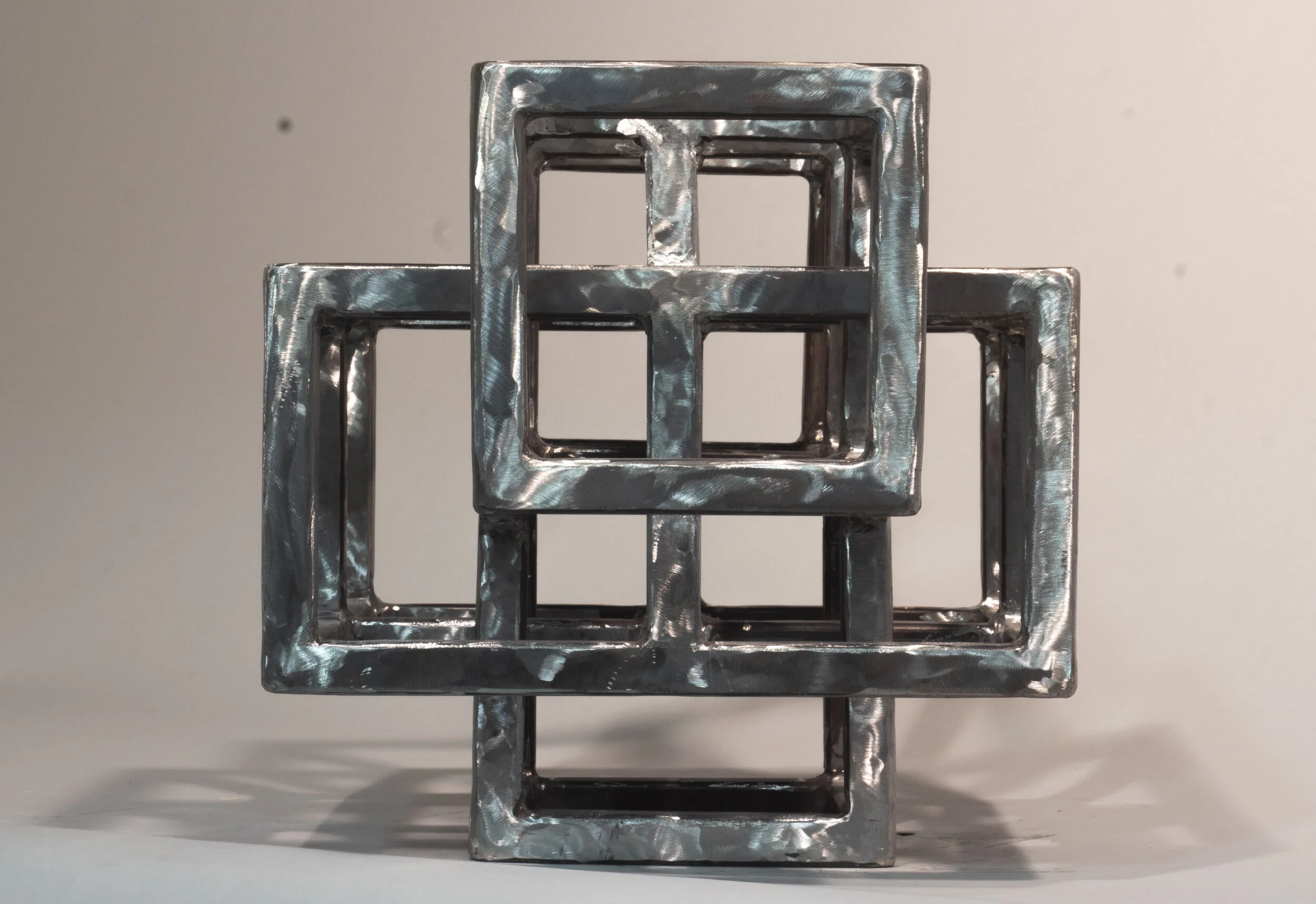

Metal Sculpture

50lbs, 15”x15”x22’

The Process

I started with two ideas in my head the first being a fully functional Skateboard, but my teacher advised that the engineering needed may be a little too advance, so I went to my backup, a cube sculpture. I had two references in mind, one being a picture my dad sent me from a metal shop near him and a cube optical illusion both displayed below. I learned how to weld for this project and it was honestly an incredibly fun experience. At first I was having issues making clean welds, but halfway through the 3rd cube something clicked and I started zipping away. I started with a 3D model made in Fusion 360, then sketched out each piece needed, with measurements, on paper. After doing the math I discovered my original larger version would have costed well over $100 and that is pretty out of my broke college student budget. So I halved the scale and it was more affordable, but I still wanted it to be as big as I could afford. After several calls to Scott Bolt, I got prices for different lengths and sizes and I built three or four more models in Fusion 360 to see a “realistic” version of my idea. I wanted to remain chunky but balanced so after my original 12 inch design I fell on 8 inch cubes with 1 inch square tubing, 1/8th inch thick because I wanted room to mess up, just in case. I rented a truck to pick the metal up because I was afraid I wouldn’t be able to fit in my car, I just didn’t do any math in my head and could have easily fit 8, 6 foot tubes in my car. I knew I could fit the Tubes in my car because I did it to take them to school, so that was a very wasted 60 dollar addition to the budget.

Optical Illusion Reference

My obnoxious notes to help me build this thing

Dad’s Picture Reference

Day 1

I came in Saturday at 11am, when the lab opened, and spent the first 5 hours cutting the pieces and grinding them, prepping to weld. I went home, showered off layers of metal dust, and came back at 7pm for 5 more hours of lab time. During the night period I started welding and got the base as square as I could possibly, I struggled to get them square at times because the metal moves as it cools down, but I was able to square it up with heavy use of vice's.

Making sure my measurements lines up

Cutting station

Cut and ground down with beveled edges

My fleet of metal for the first three cubes

Framing the top to confirm the base is as square as possible.

“Finished” welded base with the tops in the background

Cleaned up work station, showing off progress

End of Day 1

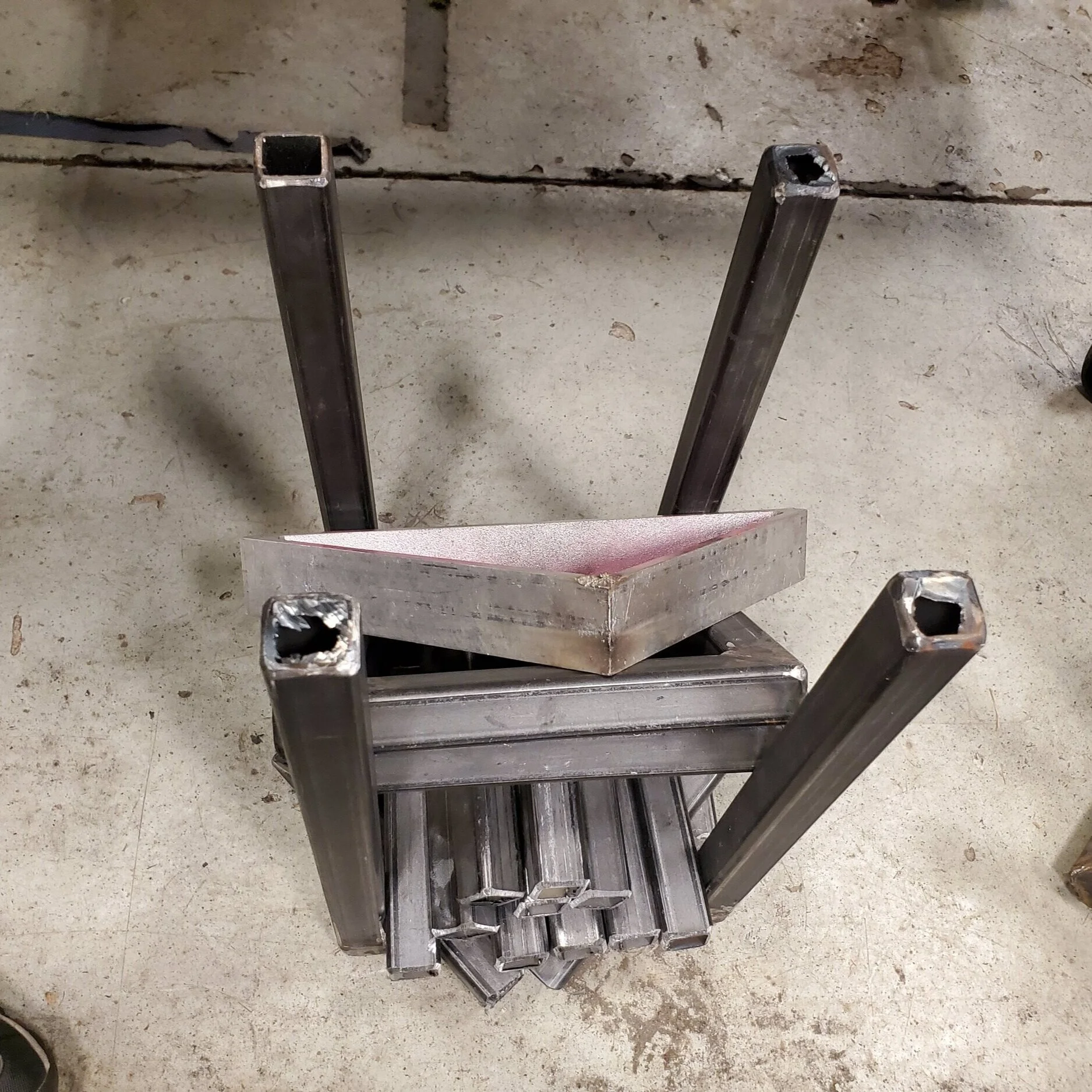

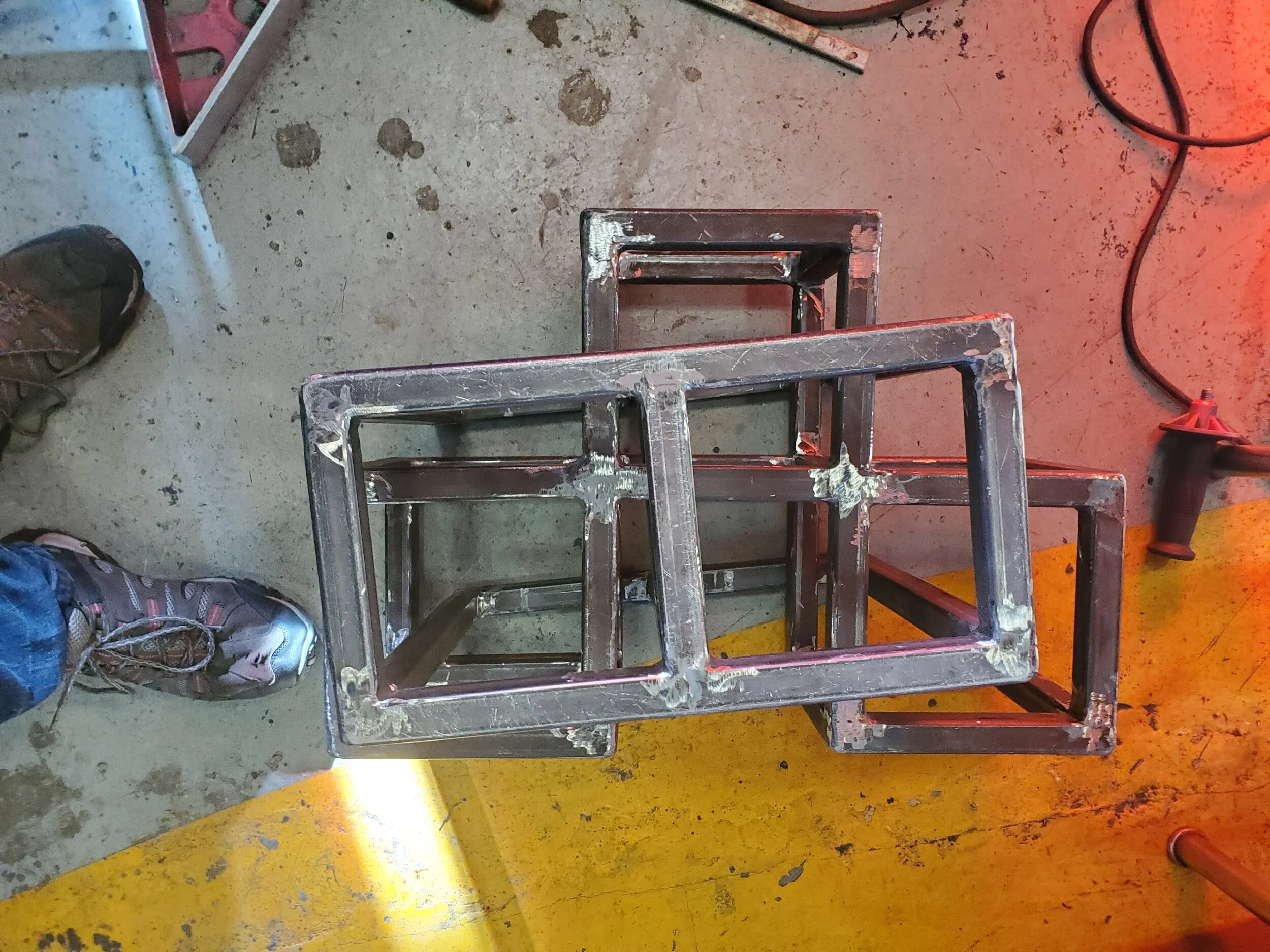

Cleaned up, stacked, and put away for day 2.

Day 2

This day started 9am, class time, and I was determined to finish the first 3 cubes of my creation. I started with attaching the two cube tops first to again confirm squareness within the peace. I found it very hard to be a perfectionist in welding, but I’m too stubborn to let that stop me.

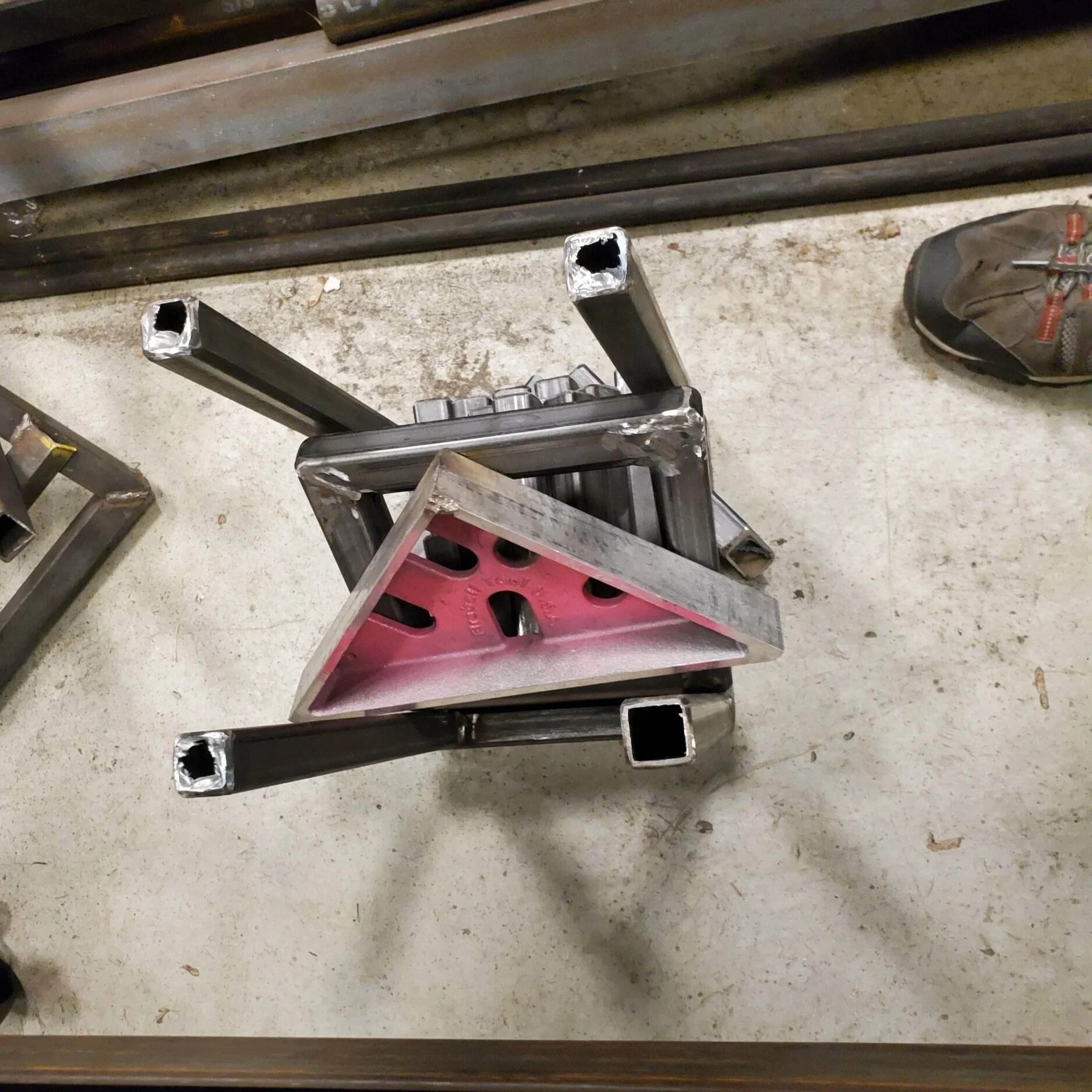

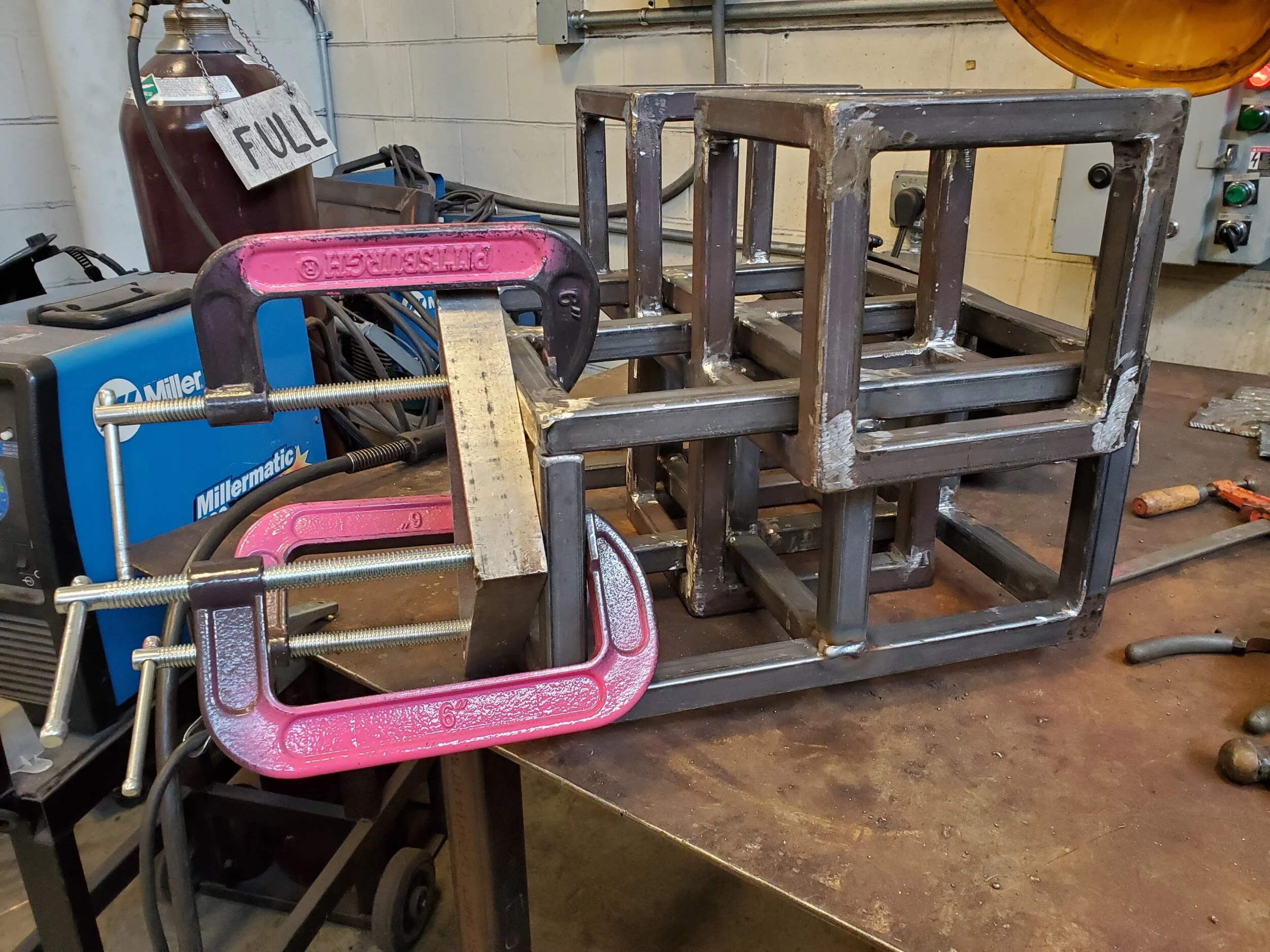

My setup for perfect squaring at the cost of my hands and space to weld

Alternate view of this contraption

Stacked away to finish the morning

Alternate view end of morning stack

End of Day 2

I left class at 2 to eat and arrived back in action around 7 for lab hours and left about 10 that night. My setups got more complex as some warping tried to steer my piece in the wrong direction, but again at the cost of my hands and time I got it lined up perfectly-ish.

Almost done

Finished for the day

Day 3

By this point I feel like a professional welder, so I had an easier time cutting and grinding the pieces for the next 4 cubes. I guess I got really into it this day because I got there at 9am for class and left at 7pm without even a snack break. I spent the morning section cutting, grinding, and setting up the base for the new cubes. After I got the bases down I wanted to be careful and plan each on out, so I’d be able to get in with a grinder and clean up. I started with the pieces that don’t intersect first to give it a solid starting point. After welding, grinding, and squaring that piece, I set it in the 3 cubes and started the first intersecting pipe, no going back now. I had to use a hammer to get some pieces in and had to fill others with mig wire, so my measurements may have been off by a few millimeters here and there. I got all but 5 bars of the final 4 cubes done, but I felt exhausted and needed food, so it rested in my head incomplete for the day while I drove off and got some Burger King.

Cut pieces for the day

Grinded and stacked neatly for my weird desire for perfection

4 Cube base

Base with support system

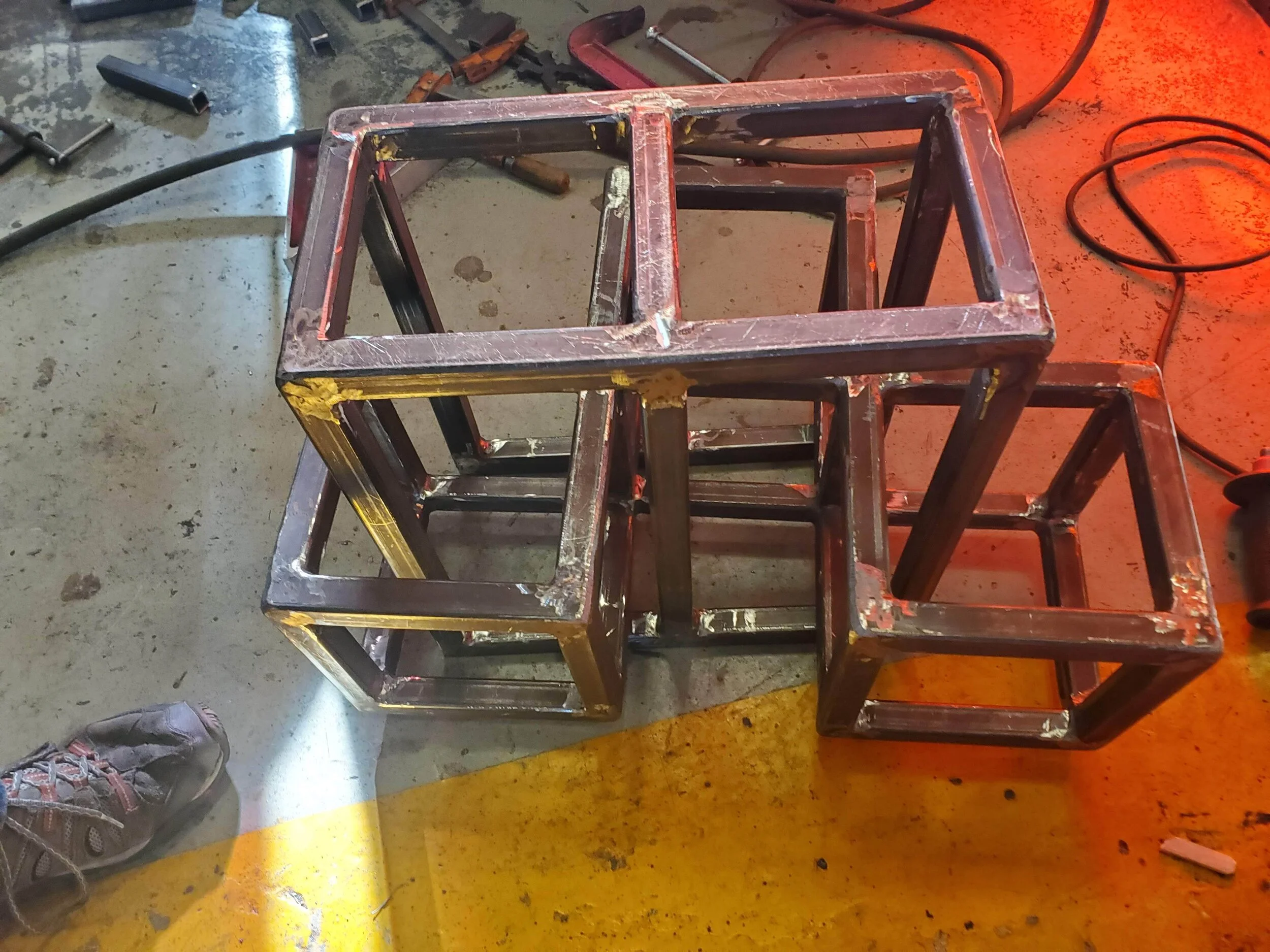

A cool red filtered pic of the no going back part of the sculpture, where my two sets of cubes are now permanently connected

Alternate view of initial connection

one more for the heck of it I was pretty excited at this point to see my piece slowly coming to life

Front view, final form, Day 3

Top view, final form, Day 3

Side view, final form, Day 3

Day 4

Ah yes Day 4, 5 bars to go and 2 connection points to complete the project, sounds simple right? Well my perfectionism took over on day 4 and after welding together the last 5 bars I decided to grind, and brush as much as I possibly could to get this really wicked shiny metal pattern on it. So Day 4 starts around 10am and comes to an end around 2pm, when lab hours are over. I was welding every other day, so I was incredibly sore at this point, but still determined to make something badass.

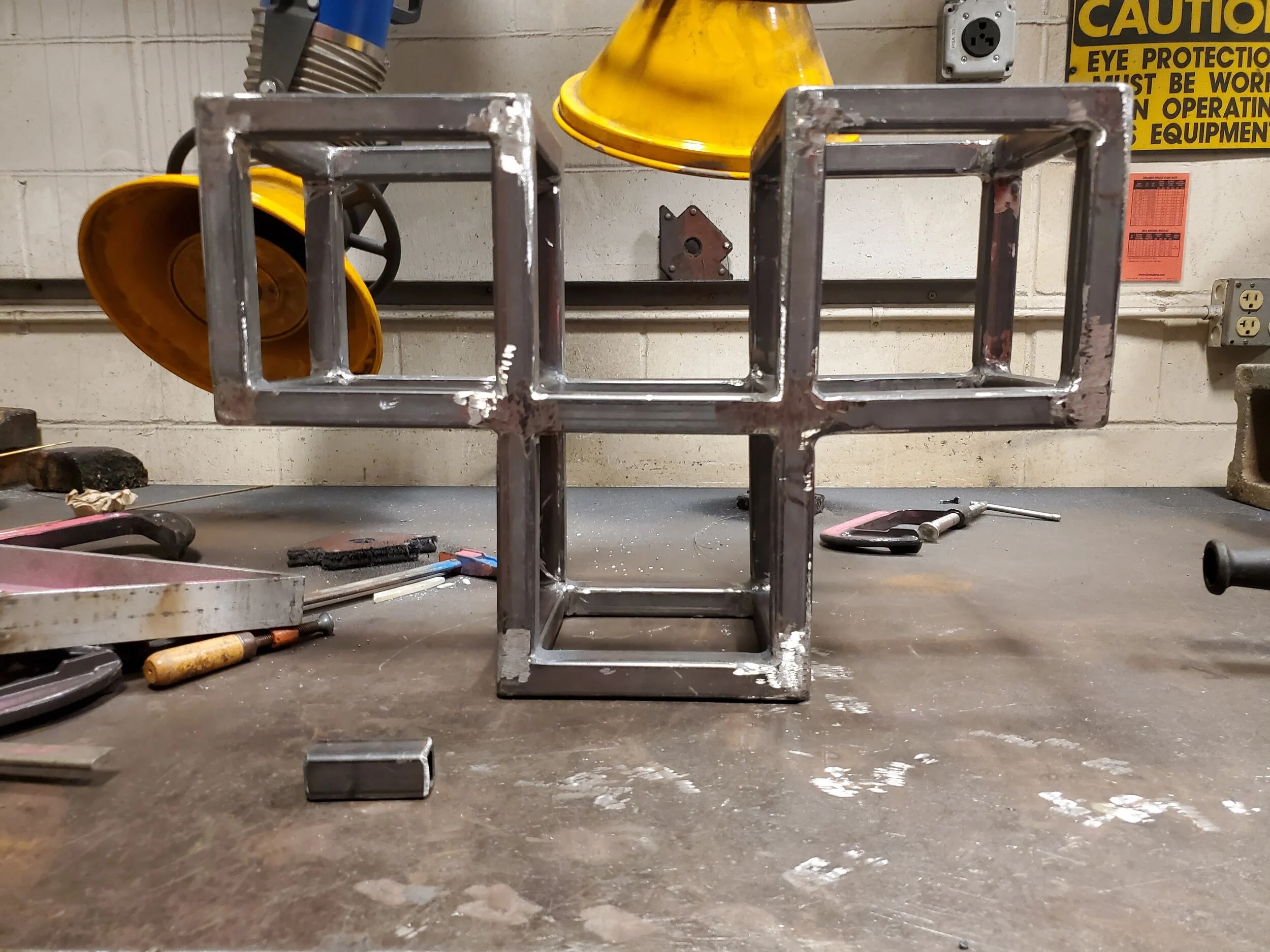

Less intricate jig’s as the piece was becoming more rigid and perfectly square as I added more bars

Alternate view of simpler jig

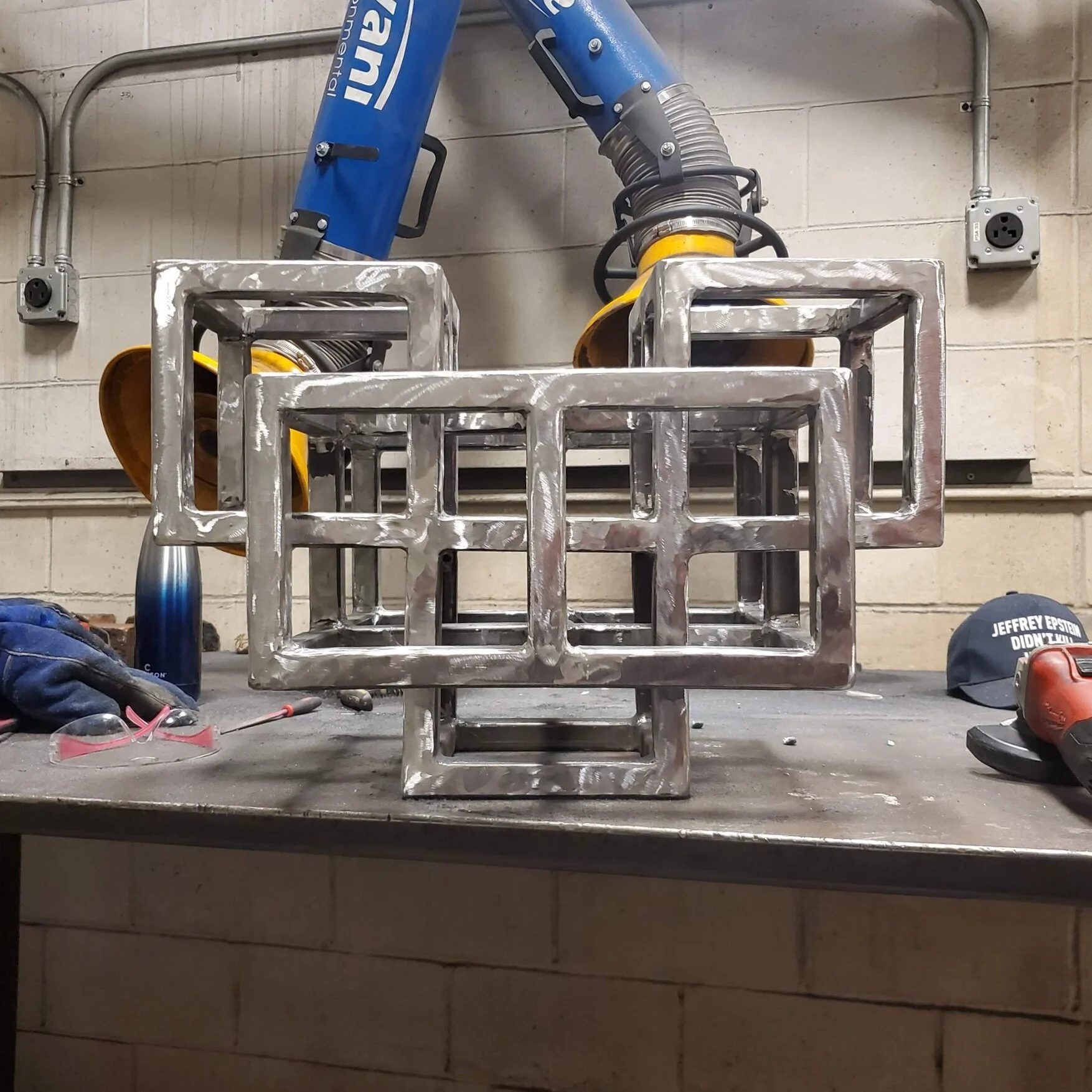

The 7 cubes are complete, just in time to clean them up

Front view, end of Day 4, the middle is propped up on a brick to emulate the final form

Alternate view, end of Day 4

Side view, end of Day 4

Alternate side view, end of Day 4

Day 5

You’d think the day I combine the cubes and clean up all the sides I’d take a lot of pictures, you’d be wrong, my phone died after I took one picture of the complete form which I will give you. So without pictures I’ll describe Day 5’s progress. I arrived at 7pm for lab hours and spent hours grinding and brushing the metal to get the finish on almost every pieces of metal I could reach. I then squared up the two attachment points, welded them to the 4 cubes, flipped the sculpture over, squared the cubes to each other, and welded the final welds of the piece. I then proceeded to grind and brush for a couple more hours, since the welds took me less than 20 minutes. I used a wire brush to clean burn marks, hand files and the grinder to clean corners, and the brush to clean as many flat areas as I could reach.

The final form

Day 6

The final day in the shop. I spent all morning going in with the brush grinder and small dremel like bits to clean up as much metal as I could. I finished it quickly so I could take professional pictures of it for display and then race over to a photoshoot for another class. While cleaning it up I noticed I couldn’t get it perfect with power tools, so I did my best and went home to research. I discovered I can sand it by hand using very coarse sandpaper and it’s going to take a few days and a lot of paper to clean it up to my liking. For now the professional pictures look good and will meet the class requirement, but to display it as a proper art piece I am going to sand it till I’m happy with it. Making this piece forced me to practice patience, due to every mistake needing at least ten minutes of grinding to fix. Before I started this project I had a rough idea how to weld and I had done it very badly before, but by the end I felt like I could mig weld just about anything, half decently at least.

Extras

I also wanted to share minor injuries throughout the piece

A stomach burn where I dumbly pulled a piece I just welded into my chest and it burned through my welding jacket and t-shirt without making a hole, key note: freshly welded metal is super hot

Minor bruising from turning some of the vises as hard as I could